[bootstrap_tab name=”Mechanical Vibrations” link=”tab1-slug” active=”active”]

Machinery Vibrations

Services include measurements during run up and coast down, and steady state operations for severity assessment and diagnostics for root causes. Steady state vibration analysis include FFT spectrum, time waveform analysis and orbits. Advanced signal processing using wavelet and higher spectral order analysis are available. Transient analysis includes bode and cascade plotted against speed, load, pressure and other process dependent parameters. We extensively use Operational Deflection Shapes (ODS) to provide an insight to the dynamic behaviour of the machine train.

We undertake machinery diagnostics services for large turbo‐generator sets, gas and steam turbines, centrifugal and reciprocating compressors, pumps, hydro‐turbines, industrial fans and air handling units. We have successfully diagnosed resonance, cracked shaft, rubs, soft foot, flow induced vibrations, generator problems in addition to common faults of unbalance and misalignment.

Analytical services include real rotor response calculations for rotor bearing systems, critical speeds, mode shapes and unbalance rotor response.

Left to right: Typical steam turbine blades failure | 500 MW steam turbine, TNB Kapar

Machine, Structure & Piping System Vibrations

Machinery vibrations are usually compounded with structural supports, machine skid vibration problems and piping system resonance. Vibration investigations for root causes of recurring machinery failures require measurements of the supporting structure and piping systems. This shall include run up and coast downs transient analysis, as well as bump tests during plant shutdowns to determine natural frequencies of the entire machine structural support and piping systems.

We offer comprehensive machine structure and piping system investigations using multi‐channels measurements for large system. Post processing include Operational Deflection Shapes analysis. The investigations often include finite element analysis of the piping systems and machine skid. Such an approach is often necessary in solving design and operations embedded faults.

Our experience include entire 500 MW steam turbo‐ generator sets that includes the machine train, turbine island, steam pipes, condenser and other connected seawater cooling water pipes. We also have extensive experience for reciprocating compressors and gas piping systems in offshore installations.

Left to right: High pressure methanol pump with recurring seal failures due to pipe resonance, Keith | Reciprocating compressor and gas piping system, Petronas Carigali, Tukau offshore gas platform, Sarawak

ODS model of 500 MW steam turbo‐generator train, support structure, condenser, steam pipes, Kapar TNB.

MEP Noise & Vibration Control

MEP (mechanical, electrical and plumbing) equipment associated with building systems and industrial processes are often some of the major sources of noise and vibration in a building or a plant. Adequate and the least costly noise and vibration control is best achieved when addressed during design stage of a project.

Services undertaken includes analysis, design, specifying and selection of devices and other measures on keeping unwanted noise and vibration from building systems and equipment out of spaces to match design criteria of the space. This also include site inspections to ensure correct installation and final check out tests. We also undertake assessment, investigation and recommendations for remedial solutions of excessive noise & vibration from MEP equipment and plant rooms.

Noise Vibration Harshness

Noise & Vibration Harshness (NVH) are important requirements in vehicles (cars, trucks, buses, tractors) with increasing expectation of consumers for quieter and smoother rides under all road conditions.

We undertake measurements for severity assessment of vehicles, investigations to determine root causes of excessive NVH, and formulation of remedial solutions.

We also assist vehicles manufacturers in their design development, trouble shooting of NVH complaints in specific models, and ride comfort NVH improvements. Our analysis are based on finite element analysis to obtain dynamic response of the vehicle structure (body in white) and vibro-acoustics for determination of cabin noise using statistical energy analysis(SEA). The analysis are also supported by measurements done in‐house at the manufacturers’ facilities. Our experience included some of Proton (including UK export model) and container haulage trucks (“tractors”).

Left to right: FE model of Proton Wira |

Calculated sound pressure levels inside Proton Wira from SEA model

Left to right: Haulage tractor for solid body motion analysis using SAMCEF | Geometric model of haulage tractor (Pro‐E model)

[/bootstrap_tab]

[bootstrap_tab name=”Predictive Technologies” link=”tab2-slug” ]

Condition Monitoring

Services offered are setting up of condition monitoring programmes, selection of monitoring technologies and baseline measurements.

We provide call up services to supplement the Plant’s condition monitoring programme with vibration measurements based advanced signal processing in additional to conventional FFT spectral analysis. We have developed and published improved methods using time gated wavelet analysis for detection and diagnosis of rubs and looseness in blades (typically in gas and steam turbine and compressors) and higher order spectral analysis for detection of faults with non‐linearity. This enable resonance to be differentiated in a vibration system without the need for a plant shut down.

Structural Health Monitoring

Schematic showing a SHM system for polyethylene rector structure

Our involvement in investigations and structural integrity assessment of large scale engineering structures in oil & gas industries as well as buildings required us to develop, install and use structural monitoring systems over extended duration.

We develop, supply, install and manage structural health monitoring systems for engineering structures and buildings. Structural health monitoring system is used to automatically measure, trend and assess dynamic parameters (acceleration, displacements, strain, acoustic emissions) and other static parameters (inclination, etc.). The system can be used to correlate load and process operations affecting the long term integrity of the structure.

Structural health monitoring is increasingly necessary in the oil & gas industry as structures are approaching design life and/or having to operate with increased loading due to increased production. Structural health monitoring should be used as an integral monitoring tool in life extension utilisation of engineering facilities.

Photo of the rector structure, FEA to validate offshore

Kertih structure response

[/bootstrap_tab]

[bootstrap_tab name=”Structural Dynamics” link=”tab3-slug”]

Structural Vibrations

Services include measurements, vibration severity and structural integrity assessment of large engineering structures and buildings. Determination of ambient and forced vibrations response, natural frequencies and mode shapes. Operational Deflection Shapes (ODS) measurements involving large scale phase matched measurements on a large scale basis under different loading conditions.

Experimental and numerical modal analysis. Finite element analysis of structure validated against vibration measurements for extraction of stress pro‐ files in structure for structure life assessment.

Seismic Vibrations

We undertake assessment of all types of ground borne vibrations and performance based seismic evaluation of buildings, bridges , industrial, petrochemical and offshore facilities.

Using state of art numerical simulation tools we assess seismic performance by examining non‐linear dynamic response of the structure and its foundation together.

We also design seismic vibration protection technology such as base isolators and energy absorbing devices as retro‐fit and new buildings and structures.

We have undertaken vibration acceleration monitoring of dynamic response of buildings in the Klang Valley over long term durations that captured seismic excitation from earthquakes in Sumatra. Such data can be used for validations of numerical simulation and structural integrity assessment of buildings and structures for seismic events.

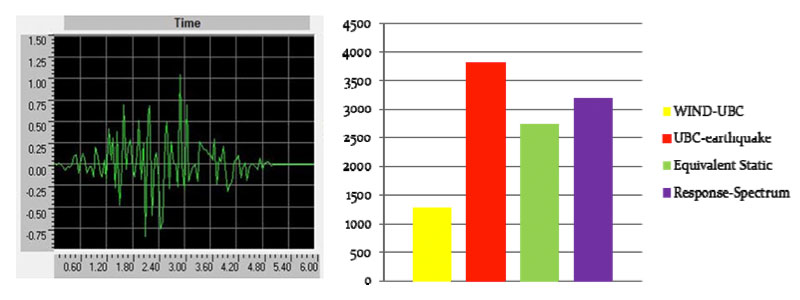

Wind and seismic vibration monitoring in a building, KL Sentral

Time histories of building

response (velocity mm/s) during earth tremor in the building

Earthquake Engineering

The Seismic Earthquake Engineering Research (SEER) Research Group of the Institute is highly regarded in the region for seismic analysis and risk evaluation. Earthquake engineering is becoming an issue of increasing concern In the region with increasing seismic activities. The Institute brings to the industry multi‐disciplinary expertise in seismic engineering, dynamic analysis, structural integrity assessment and vibration control.

We undertake seismic hazard assessment, seismic structural vulnerability and structural seismic health monitoring, earthquake engineering, seismology, earthquake resistant design and earthquake fault mechanism studies.

Our experience included undertaking seismic hazard analysis of peninsula Malaysia for structural design purpose for CIDB (Construction Industry Development Board).

From left to right: Earthquake and tremors causing motions and potential damage to assets | FEA of KLIA air traffic control tower with seismic motion

From left to right: Building response during earthquake, KLIA ATC tower | Comparison of loading for wind and earthquake

Wind Induced Vibrations

We undertake wind engineering analysis to determine structural loading and wind‐induced dynamic response for buildings, towers and other tall structures.

We also use Computational Fluid Dynamic (CFD) analysis to supplement wind tunnel testing studies to visualise wind flow around buildings. Our dynamic analysis of building response are based on 3‐D non linear analysis for different wind speeds and UBC profiles.

Results of the dynamic response can be used for assessment of human response of wind‐induced motions.

From left to right: CFD 3D modeling of buildings in KL Sentral | Pressure profiles from wind CFD analysis

From left to right: KLIA Air traffic control (ATC) tower | Dynamic response of KLIA ATC tower

Human Induced Vibrations

The London Millennium bridge excessive lateral vibrations (wobbling) during opening day brought into focus concerns of human induced vibrations in foot bridges. Similar concerns occur with stadium and terraces of halls with long spans due to crowd synchronized excitation. Of particular concern are any structures with natural frequencies below 5 Hz (BS 5400 Part 2).

We undertake dynamic analysis to determine natural frequencies and dynamic acceleration response to synchronized human footfalls for assessment in accordance to BS 5400 Part 2, Euro‐ code 4 and BS EN 1990:2002.

We design solutions that generate high level of damping using viscous dampers and also de‐tune natural frequencies of the structure with tuned mass dampers. We also assist Structural Engineers in their re‐design of the building structures to increase structural rigidity thereby increasing the fundamental natural frequencies of long span floors. Our involvements involved input during design as well as situations during construction where it was apparent that a human induced vibration problem exists. Our analysis and design solutions are validated with testing during construction and during usage.

Vibration Isolation & Damping Design

Reduction of vibration and noise often requires vibration isolation and/or damping. Vibration isolation and dampers are required in diverse applications ranging from structural integrity, human sensitivity and to ensure ultra‐low ambient vibrations for vibration sensitive equipment in electronics and micro‐surgery medical facilities.

We undertake analysis and design of isolators and dampers, including tuned mass dampers. The design and optimisation based on multi‐DOF transmissibility analysis as well as FEA.

Our experience included air mounts for laboratories, industrial facilities and theme park rides (motion simulators), tuned mass dampers for bridges and machines, and electronics and medical microscopes.

[/bootstrap_tab]

[bootstrap_tab name=”Noise” link=”tab4-slug”]

Environmental Noise

We are acknowledged by all government agencies (Dept. of Environment, Malaysian Highway Authority, City Halls, etc.) and the Industry as the leading environmental noise expert in the country. With the DOE, we set benchmarks and best practices for noise measurements, modeling and assessment in the country.

We offer comprehensive services in all areas of environmental and industrial noise. The services include measurements, monitoring, investigations, analysis and detailed design for noise control, specifications and site assistance for noise control works.

Aircraft noise is an example of environmental noise concern in residential and hotels development.

EIA Noise & Vibration

The Institute has key personnel registered with DOE as Subject Specialist for Environmental Impact Assessment (EIA).

Power station located adjacent residential land use is a particular concern.

Industrial Noise

Services ranged from measurements for in plant and environmental noise for occupational safety assessment and community annoyance to detailed analysis and design for noise control. We also undertake site investigations to determine severity and causes of excessive or non‐compliance noise emissions.

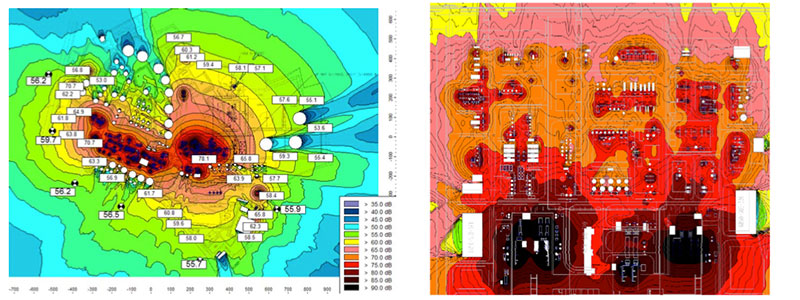

Our analysis include 3‐D noise modeling of the entire industrial plant or area of concern, with noise sources to represent the plant under existing conditions and thereatier with mitigation options. We use state or the art industrial noise modeling software (Cadyna‐A) as well as our own in‐house developed noise calculation software for specific applications.

Our experience include identification and modeling for low frequency sound and airborne sound induced vibrations from industrial facilities.

From left to right: Petronas petrochemical complex in Kertih | Gas compression package, Sarawak offshore platform with noise levels >85 dBA.

Petronas petrochemical complex in Kertih

Highway Noise

All new highways development and highway expansion projects in Malaysia require a Detailed Noise Study, and where noise mitigation is required, a Design Brief for Noise Barriers. The Institute is the country’s leading expert in highway noise, and is highly regarded by the Malaysian Highway Authority (LLM).

The noise study and detailed design of noise barriers are undertaken using Cadyna‐A software. Noise are calculated with considerations of highway design parameters including vehicle speed, traffic volume and mix, gradients, etc., pavement type as well as shielding and reflections for outdoor noise propagation. Noise are calculated without and with variations in noise barrier designs.

Noise monitoring are undertaken before highway development (baseline), post construction pre‐opening, and during highway operations for compliance assessment.

We also provide services for mitigation of traffic noise intrusion into buildings affected by new and existing highways. High rise and high end developments are of particular concern. The services include design and optimisation of glazing selections based on 3D noise modeling with noise levels determined for the entire building facades.

From left to right: SPRINT Kerinchi Link affecting Taman Pantai (on LHS KL bound) | SPRINT Penchala Link approaching Mont Kiara (KL bound)

3D noise modeling to assess impact of Penchala Link on proposed high end residential development adjacent highway (Serene Kiara)

Railways Noise & Vibration

Railways (Mass Rail Transit and LRT) shall form the backbone of public transport in the Klang Valley. Urban transit railways are inevitably built amongst densely built up populated areas. Airborne noise and ground‐borne vibration and noise are major environmental concerns in such development.

The Institute undertakes noise study and design for noise & vibration mitigation measures for railways. Our work are based on noise modeling which includes considerations of existing noise sources. Our involvement covers the planning stages, environmental impact assessment, line wide scheme design and detailed design. We also provide assistance during construction including supervision and testing & commissioning.

We also undertake detailed design of track form isolation and building isolation for ground‐borne vibrations and noise affecting buildings built adjacent and above railway lines.

From left to right: Noise barrier design for new Klang Valley MRT Sg Buloh Kajang line | Typical results from noise modeling for KVMRT adjacent residential house

From left to right: Hotels in KL Sentral built over KTM railway lines isolated with ballast mats designed by UTM | Ground‐borne vibration and noise due to rail wheels interaction made worst by deterioration in wheels and rails

Aircraft Noise

We provide services in measurements, analysis, severity assessment and design of sound insulation for aircraft noise intrusion for development and buildings (hotels, convention centres, etc.) built near airports and below flight paths.

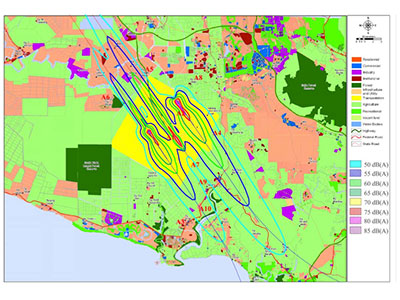

We also undertake airport noise modeling and assessment in airport master plan and Environmental Impact Assessment. Our airport noise modeling are undertaken using industry’s standard FAA noise modeling software (INM) that considers air traffic volume and aircrafts types, air tracks and airport operations (wind directions) and other governing parameters.

From left to right: Aircraft take offs often results in the highest noise (Lmax levels) | Glazing design and selection are critical for aircraft noise. Glazing in KLIA landside Hotel rendering aircraft noise inaudible

Noise contours (Leq) over the KLIA Sepang with new Runway 3 for KLIA2 LCCT project.

Noise Barriers Design

The Institute undertakes detailed design of noise barriers and enclosures for mitigation of noise from highways, railways and industrial facilities.

Design are based on 3D noise modeling with representation of buildings and large objects in the site of interest. The noise models are validated against measurements such that the existing environment are adequately represented that would include all existing noise sources.

We recommend barrier types to match the project technical and budget requirements, develop detailed engineering drawings, and assist in the tender and construction works supervision, and testing upon completion.

Our clients are typically highway concessionaires, railways scheme designers and operators, industry plants owners and contractors (in design and build projects).

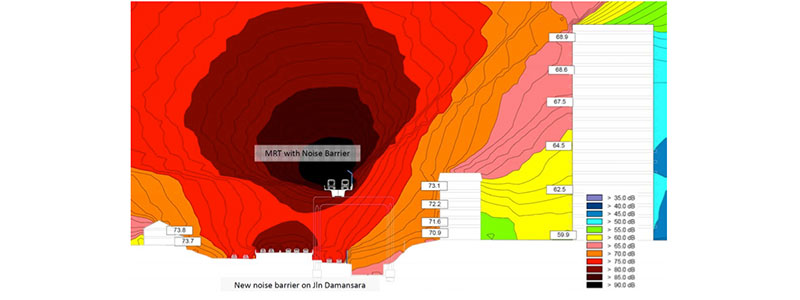

From left to right: Noise barrier design for new Klang Valley MRT SBK Line | Semi‐enclosure design for new Klang Valley MRT SBK Line

Results of noise analysis to establish design heights of MRT and road re‐alignment noise barrier

Construction Noise & Vibrations

Construction noise and vibration is often deemed the most annoying noise and vibration affecting the community as this noise is imposed onto the existing environment.

We undertake noise and vibration modeling, assessment and design of mitigation measures for construction and demolition works.

Our recommendations include selections and effectiveness of temporary noise barriers, review of construction work process, staging of demolition works, effects of multiple and simultaneous piling, use of semi‐enclosures and barriers for equipment.

From left to right: Typical construction site in urban areas, Johor Bahru | Erection of temporary noise barriers at Klang Valley MRT con‐ struction site fronting houses

Noise analysis to assess MRT construction noise affecting houses showing requirements and effectiveness of temporary noise barrier.

Oil & Gas Noise Study

We undertake noise study required in all oil & gas projects, either during preliminary design (Front End Engineering Design) and detailed design development.

We review and develop noise data sheets for vendors specifications and procurement compliance, establish noise maps, identify noise hazards and propose mitigation measures.

Noise modeling are undertaken using world leading noise modeling software Cadyna-A. Our 3D noise modeling and assessment are aided by our extensive experience in noise measurements and investigations in petrochemical facilities that include refineries, petrochemical plants and offshore drilling and production platforms. This includes database of noise data of equipment and processes.

We also have extensive experience in design of acoustics enclosures, lagging and sound attenuators. In recent years, we also have investigated and solve low frequency noise and noise induced vibration problems affecting Living Quarters in offshore platforms, the community for onshore installations.

From left to right: Refinery plant expansion noise contours | Elastomer plant noise contours

View of 3D model representing petrochemical plants (Plants not identified here due to project’s confidentiality)

[/bootstrap_tab]

[bootstrap_tab name=”Acoustics” link=”tab5-slug”]

Building Acoustics

Our services for building acoustics covers all aspects of sound transmission—airborne and structure-borne noise and vibration We develop and recommend cost effective solutions for challenging applications. These include airports, studios, auditorium, convention halls, hotels , apartments, high quality buildings, technical spaces and laboratories.

The solutions cover building envelope and facades (glazing, walls, roof, etc.) as well inter rooms and inter‐floor constructions.

A particular problem in the region relates to rain impact noise on light weight roofs. Noise generated from roof during heavy rainfall often result in unacceptable noise intrusion, and metal roofs need to incorporate rainfall impact sound insulation. We are the pioneer in this region to develop testing with simulated rainfall under controlled conditions to optimise roof constructions.

We also undertake projects for special applications such as studios, test labs and vibration sensitive spaces (wafer silicon plants, electron scanning microscopes, etc.) that require floating floors and rooms constructions.

From left to right: Glazing at Danga Bay, Johor | Metal roof for KL Convention Center designed by UTM to render rain noise inaudible in Plenary Hall and Convention Halls.

From left to right: Acoustics door for Film Studio at Pinewood Malaysia Studios, Iskandar | Vibration isolation mounts for floating floor during construction at Pinewood Malaysia Studios

Interior Acoustics

Interior acoustics design is necessary for the control of reverberation and echoes in performing spaces, and other functional where clarity of speech and music Is important. We develop acoustics solutions to meet acoustics functionality integrated within the interior design intent of the spaces. Very often innovative solutions need to be developed in instances where architectural form and ID intent challenges acoustics norm. Our design and recommendations are based on comprehensive analysis and electro‐acoustics modeling.

We have provided interior acoustics designs for iconic projects and halls in the country.

From left to right: Ray tracing of acoustic model of UMS Convocation Hall, Sabah | Plenary Hall, Kuala Lumpur Convention Centre. Interior acoustics design by UTM

Artist impression (developed during Project design stage) of Kuala Lumpur Convention Centre Plenary Hall

[/bootstrap_tab]

[bootstrap_tab name=”Monitoring & Testing” link=”tab6-slug”]

Testing Services

In addition to project specific measurements and monitoring, the Institute undertake Measurements, qualification and compliance testing in Acoustics, Noise & Vibration and Seismic Engineering.

Acoustic testing are on‐site field tests for quality assurance and performance ratings. Test include on site installed FSTC / Rw’ airborne sound insulation, sound absorption, reverberation time, building services NC / NR levels, sound power level determination of equipment.

We also develop test rigs and undertake the tests for specific performance test of automotive components.

From left to right: Dynamic testing at Plenary Hall of KL Convention Center to determine floor slab natural frequencies | Airborne sound insulation testing for Exhibit

From left to right: Impact test for normalise d sound level Ln for metal roof construction | Background air‐conditioning noise In KL Convention Center Auditorium

Environmental Noise & Vibration Monitoring

The Institute undertakes comprehensive noise and vibration monitoring for assessment of noise and vibration climate, from all types of noise sources (industrial plants, airports, high- ways, railways, commercial activities, discotheques, etc.) determination of baseline levels for design and EIAs, and to monitor construction noise and vibration as part of the Environmental Management Plan (EMP).

We have the largest inventory of noise and vibration monitoring instrumentation in the country, including permanent outdoor noise monitoring units for long term permanent noise monitoring of airports and construction sites.

We have also developed in collaboration with an OEM of smart permanent noise monitoring units with real-time 3G Web based monitoring for the Klang Valley MRT tunnels and Station construction sites. We also undertake the management and reporting of the permanent noise monitoring at these KVMRT (T) construction sites for compliance reporting to DOE.

From left to right: Semi‐permanent noise monitoring of construction works at Bangsar | On‐line real

KVMRT Cochrane portal construction site

[/bootstrap_tab]

[bootstrap_tab name=”Knowledge” link=”tab7-slug”]

Expert Witness

The Institute and its key personnel who are acknowledged as leading experts in the region in their respective disciplines undertake assignments as expert witness in arbitration and civil suits.

We undertake measurements and analysis for defence, critical review and verification of evidence and other technical submissions, including laboratory analysis, and other back- ground research related to issues and subject matter of the claims.

We have been involved as expert witness for damage claims for Defendants and Plaintiffs at the Kuala Lumpur Arbitration Centre, Malaysian Civil Courts and Land Hearing court.

From left to right: Damage claims from construction piling affecting adjacent house, Jalan Gurney Kuala Lumpur |

Boiler failure insurance claim by chemical plant, Banting

Claims for noise disturbance against Power Station, Port Dickson

Contract Research

Industry problems often have underlying technical and design issues that are not readily solved as a consulting assignment. This offers an opportunity for such problems to be resolved as an industry driven contract research. This presents an opportunity for us to push the boundary of knowledge and offers the research sponsor double deduction tax incentive.

The research project brief typically involves experimental work undertaken under controlled conditions in laboratory studies at UTM or set up on the actual installations at site. Field problems and failures are articulated into specific problem statements upon which suitable experimental test rig could be designed and built for laboratory studies.

The work is usually supported by parametric studies using analytical and computational analysis.

[/bootstrap_tab]

[end_bootstrap_tab]